Brochure

- Download

pdf

The uhde® entrained-flow gasification process with steam generation, which operates at elevated pressure, can be used to gasify all types of solid feedstocks (coal, petroleum, coke and biomass). It is a further development of the Koppers-Totzek process developed in the 1940s, which operates at atmospheric pressure and was specially designed for power generation applications.

The lessons learnt from more than two decades of experience in operating the uhde® PSG entrained-flow gasification process have consistently formed the basis for subsequent successful applications.

INPUT: high rank feedstocks with low ash content, or low ash softening point.

OUTPUT: CO-rich syngas as well as electrical power with high efficiency.

Main process data

up to 1,200 MWth single train capacity

Process data

Gasification pressure: 40 bar and higher

Gas temperature at outlet of gasifier waste heat boiler: 250 - 300 ℃

Carbon conversion: > 99%

Typical raw gas composition:

CO + H2 > 85 vol.%

CO2 2-4 vol.%

CH4 < 0.1 vol.%

Entrained-flow

Dry dust feed for high efficiency

Multiple burners with high availability and long lifetime

Horizontally arranged burners for high carbon conversion

Membrane wall with long lifetime

Waste heat boiler for efficient heat recovery

Operates above ash melting point

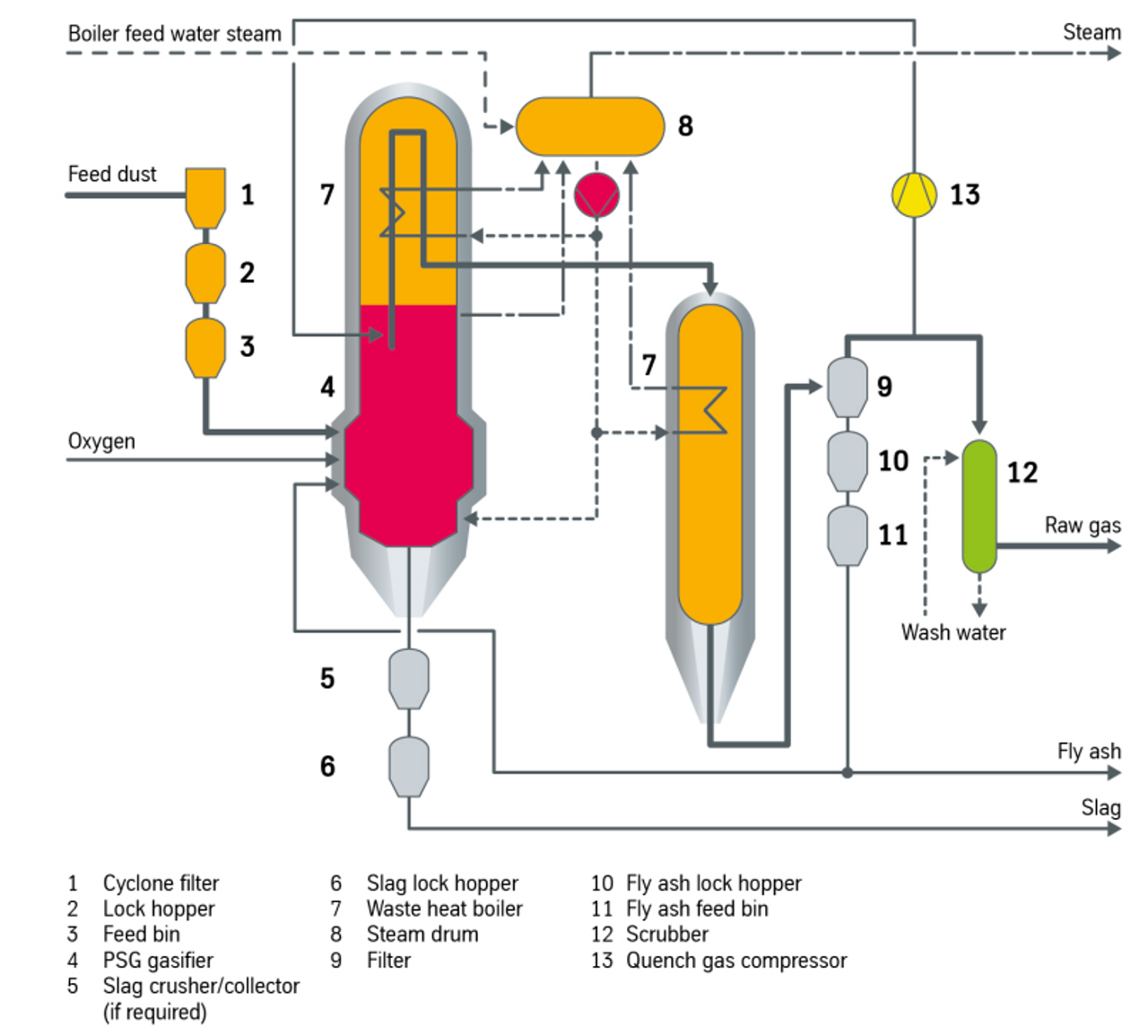

First, the feed dust is prepared in the feed preparation unit. Approximately 80% of the dust is smaller than 0.1 mm. This feed dust is then gasified in the uhde® entrained-flow gasifier using oxygen and steam as gasification agents. The gasification temperature is higher than the ash melting temperature, which allows the feedstock to be removed as slag. The cooled-type gasifier is equipped with multiple, horozontally arranged burners.

In the uhde® entrained-flow process with steam generation (PSG), the raw gas produced, which contains mainly carbon monoxide and hydrogen, is cooled in the waste heat boiler, generating steam. The gas is then dedusted in a candle filter and further treated in a Venturi scrubber.

The slag from the gasifier can be used as a construction material and the fly ash from the candle filter asa a base product in the cement industry.

The uhde® entrained-flow gasification process with steam generation was used at the world's largest single train, dry-fed, solid-feedstock-based IGCC power plant in Puertollano, Spain. For more than 17 years this plant operated with a mixture of petroleum coke and high-ash/low-rank coal as well as the occasional biomass co-feed.

Koppers GmbH of Essen, Germany, under the direction of Dr. Friedrich Totzek conducted experimental work on the gasification of pulverized coal from 1938 to 1944. The reactor was a horizontal drum with pulverized coal introduced at one or both ends, and the gasifying agent was oxygen mixed with steam. Operation was only at atmospheric pressure. The first trials were not successful due to high heat loss of the reactor. That's why the oxygen-steam mixture was brought to a temperature of about 1000 - 1200℃. To loosen-up the coal and somewhat improve its distribution, the coal dust was blown in by a superheated gas-steam mixture. As a result of the hot O2/steam mixture a very rapid ignition of the dust took place and a temperature of more than 2000℃ was obtained.

This accelerated the gasification process so greatly that the coal dust was gasified to the extent of about 95%.

In 1948 a pilot plant gasifying 25 tons per day was built in Louisiana, Missouri, U.S. These trials were followed by the building of several indusrtial scale gasifiers in Oulu, Finland(1952), Japan and France (1955) etc. In total 77 units were installes worldwide.

Currently all other dry-feed EFGs are refinements of the Koppers-Totzek process. The main characteristics were:

All types of coal can be used

Finely pulverized dried coal is fed by screw conveyer, then oxygen and steam blow in the coal at a high velocity. The flame temperature is around 1800 ℃ and the coal particles gasify virtually immediately

Pressure is slightly above atmospheric

Ash fuses and 50-70% falls into quench bath. The remainder is entrained in the gas and collected after the gas is cooled and washed with water.

Low methane content in gas (e.g. 0.1%) and no phenols or tars due to high temperature.

As the syngas was produced at low pressure it led to high costs of compression in subsequent processes. Therefore in 1973 Koppers GmbH started R&D on the PRessurized ENtrained FLow gasification (PRENFLO®)process. From 1974 until 1981, Koppers GmbH and Shell International Petroleum Maatschappij B.V. worked together on the development of coal gasification at elevated pressure. This cooperation was aimed at combining the existing knowledge at Koppers and experience with coals and with the atmospheric Koppers-Totzek coal gasification process with the existing Shell-Koppers. The first pressurized pilot plant was put into operation in 1976 (6t/d) followed by a 150t/d Shell Koppers plant that started in 1978 at Deutsche Shell's Harburg refineries.

Meanwhile Krupp took over Koppers in 1974 and became Krupp-Koppers AG. When the joint development effort ended in 1981, Shell and Krupp-Koppers seperately continued the development of their coal gasification process, Krupp-Koppers (who merged with Uhde GmbH in 1997) with th PRENFLO® Solids Gasification Process and Shell with the Shell Coal Gasification Process (SCGP). Thus, in 1984, the PRENFLO® pilot plant (6t/h) with water quench was put into operation in Essen, Germany. The PRENFLO® technology was applied first on a large scale in the Fürstenhausen, Germany demonstration plant (48 t/d) and therefore selected and realized by Elcogas S.A., Spain for the Puertollano IGCC plant. The Puetollano plant was commissioned in 1998 gasifying 2400 t/d mixture of high ash bituminous coal (41 % ash) and petcoke coming from the local mine and refinery.