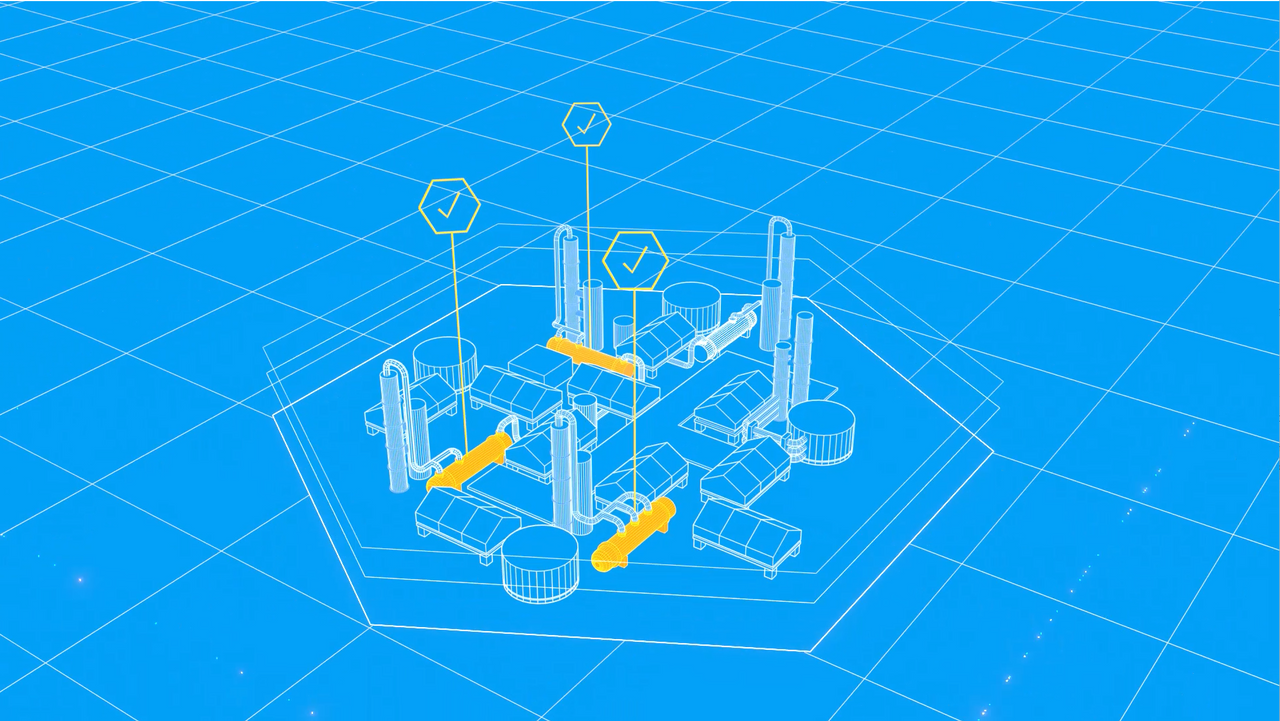

Valuable insights through virtual plant representation

The digital twin consists of multiple elements which are virtual representations of various plant sub-units or single devices.

It will be continuously (24 hours/day, 365 days/year) updated with measured data from the plant and will process this data in near real-time and run in parallel to the actual plant providing virtual monitoring, prediction and optimization functions.

If a process cannot be simulated directly (white box approach), neural networks can be used for an accurate prediction.

Your added value

Increased transparency of the plant (incl. the application of virtual sensors)

Increase process stability or flexibility

The Digital Twin assists the operator to identify different operational conditions