Climate change is now the biggest challenge that humanity has ever faced. With the global population growing and the use of fossil resources continuing to drive global warming, the problem needs to be solved. We need to provide both food and energy to the world's growing population, and do so sustainably.

At thyssenkrupp we are driven by sustainability. To stop climate change we have developed technologies that make sustainability feasible for businesses, reduce the carbon footprint of industrial value chains, and accelerate the growth of renewable energy. This is exactly what motivated us to develop our green ammonia technology ‑ perfect not only for building new green ammonia plants but also for greening up existing plants by means of a revamp.

Green ammonia applications - an astounding potential!

Ammonia is ideal for shipping green hydrogen and green energy across the globe. Why?

Ammonia has a higher volumetric energy density than hydrogen, which requires high compression and extensive cooling.

Ammonia is already being traded and transported in large quantities (around 20 million t/year) worldwide, global standards for safe handling practices have been established and the infrastructure is in place.

Ammonia cannot only be used as an energy carrier to transport hydrogen to where it is needed, but also as an emission-free marine fuel to power the ships or as a fuel for direct combustion in turbines.

Ammonia is equally essential in tackling the challenge of producing enough food to feed a growing global population as it can be used to produce low-carbon fertilizers. At the moment, 80 % of the annual global ammonia production of over 170 million metric tons is used for fertilizer production. However, its use as an electrical storage medium looks set to dwarf this figure.

Green ammonia means independence from imports and fossil resources for fertilizer production

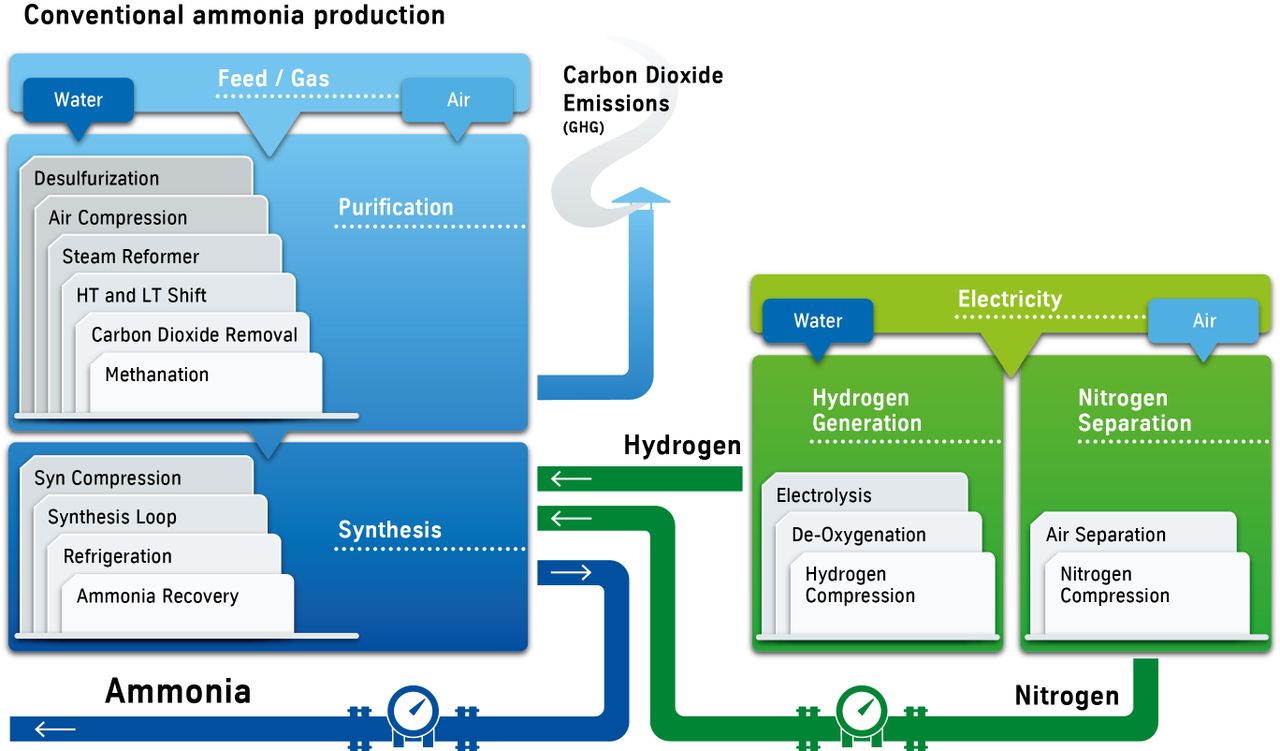

As the diagram below shows, ammonia is conventionally produced using natural gas as a fuel. Unfortunately, producing the annual 170 million metric tons the world needs accounts for around 1.4% of global fossil-fuel consumption and CO2 emissions. But luckily there is a solution. At thyssenkrupp Uhde we have developed a technology that can produce green ammonia using only water, air and electricity. thyssenkrupp Uhde integrates any kind of electrolysis technology into such a green ammonia complex.

thyssenkrupp Uhde is one of the leading technology providers in the field of ammonia with its proven uhde® ammonia process. We are a reliable and competent EPC contractor and a world market leader for ammonia plants, with more than 2,500 chemical plants built worldwide and over 100 years of experience. We are constantly improving our designs and technologies, and working towards improved energy efficiencies and higher capacities. We have a long track record of building ammonia and even green ammonia plants. We built our first one in Philadelphia, PA, USA, as early as 1932, followed by others such as in Chile in 1962, with a capacity of 50 metric tons of ammonia per day. In total we already built 4 electrolysis-based ammonia plants.

Greening of existing fertilizer plants - revamping and de-bottlenecking ammonia plants

Our green ammonia process is an interesting option for greening existing ammonia plants, as the following diagram shows. The hydrogen plant (e.g. AWE, PEM, SOEC) can be coupled with the synthesis section of your existing ammonia plant. Nitrogen is generated via air separation.

Features and ecological benefits of green ammonia production

| Features | Ecological and Economic Benefits |

|---|---|

| Premium-grade product | High efficiency, yield and reliability |

| High flexibility in ammonia production | Low maintenance requirements |

| Entire plant of a modular design | Fully modularized technology for all capacities, resulting in low installation costs |

| Proven design for small-scale ammonia plants | Climate-friendly feedstocks: No CO2 emissions (depending on E-power source) |

| Proprietary Uhde® converter design | Independent of natural gas resources |

| Worldwide proven technologies at scale | Well-referenced electrolysis and synthesis design |

| Fast / dynamic response to fluctuating power input | |

| All technologies from a single source | |

| EPC competence with a strong holding company | |

| Know-How and experience |

Contact us

Innovative chemical engineering starts with one conversation.

Get in touch today!

/thyssenkrupp_logo_claim_d.svg)